Milling

The key to a consistent quality in drug formulation relies on homogenized ingredients in terms of particle size.

Milling is one of the most common techniques to help break down large particles to finer ones, which is used for formulations of different drugs.

The pin mill and hammer mill is a mechanical process used for gross milling of large particles greater than 1mm, crushing them into small powder form, usually below 100 microns.

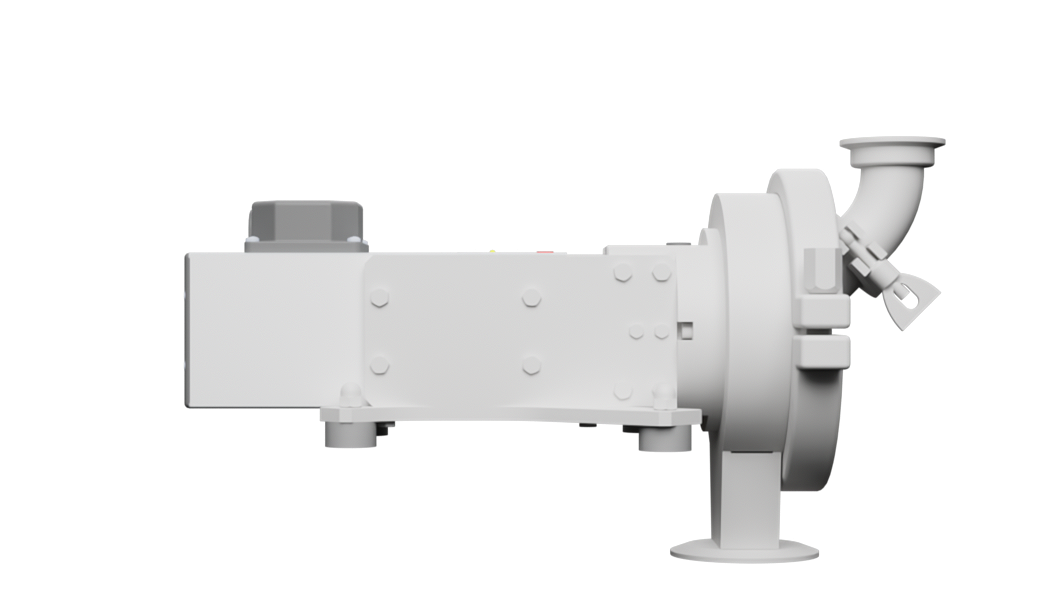

Schedio offers a milling body predisposed for the installation of both pin and hammer mill within.

Pin Mill

The equipment uses a rotor and stator with a special comminution geometry to allow the powder milling. The parts can easily be replaced with other disk geometries in order to set-up the best configuration depending on product characteristics.

Hammer Mill

The powder enters the mill through a front opening, into the milling chamber.

A rotor presses the powder against a sieve, which selects the particles according to its mesh dimension. The milling body is predisposed for the assembly of both hammer and pin mill.

A rotor presses the powder against a sieve, which selects the particles according to its mesh dimension. The milling body is predisposed for the assembly of both hammer and pin mill.