Classification

A homogeneous particle size distribution is key to a predictable and consistent dissolution profile.

Given a certain particle size distribution, the classifier separates either fine or gross particles from a certain particle size distribution. The process uses the same classification principle of the opposite jet mill.

The dynamic classifier uses the same particle separation principle of the opposite jet mill, to separate particles of significant different particle size distribution. It can be used to separate or remove a portion (either fine or gross) of a certain particle size distribution from the final product. It also helps with removing agglomerates or un-micronizable particles from the final micronized powder.

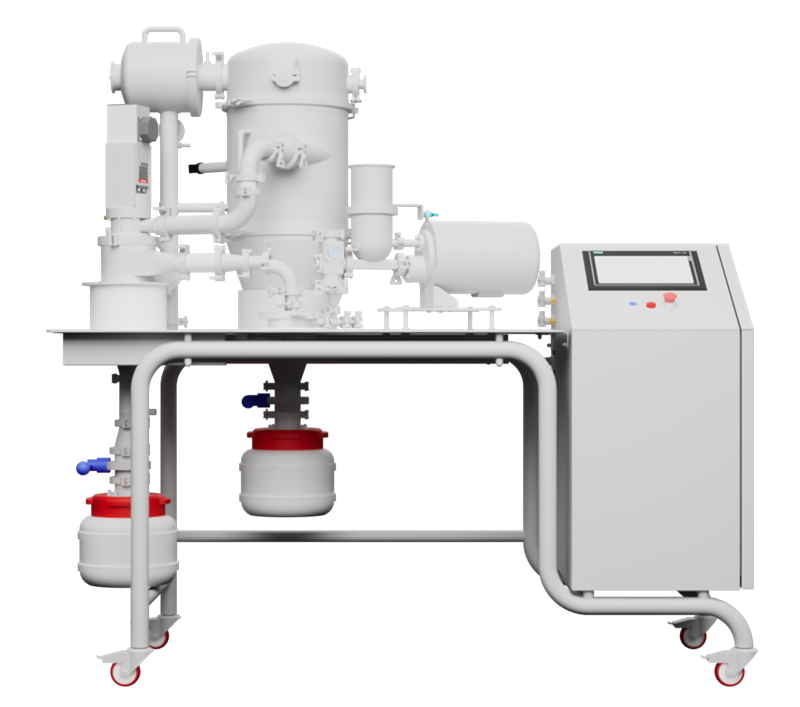

The dynamic classifier can be used as a stand-alone unit, or in line with a jet milling unit

The final particle size distribution is mainly determined by a combination of:

- Classifier speed

- Air barrier classifier pressure

- Inlet powder particle size distribution